Share optimized solutions, professional valve knowledge and industry news

Please enter the relevant terms or keywords you need to consult, and relevant articles will appear in the search results. If you can’t find the answer you need, please feel free to contact us and we will be happy to help. Or you can directly send an email to beauty@shefmon.com

What Is a Professional Packaging Process for Aesthetic Equipment?

- shefmon

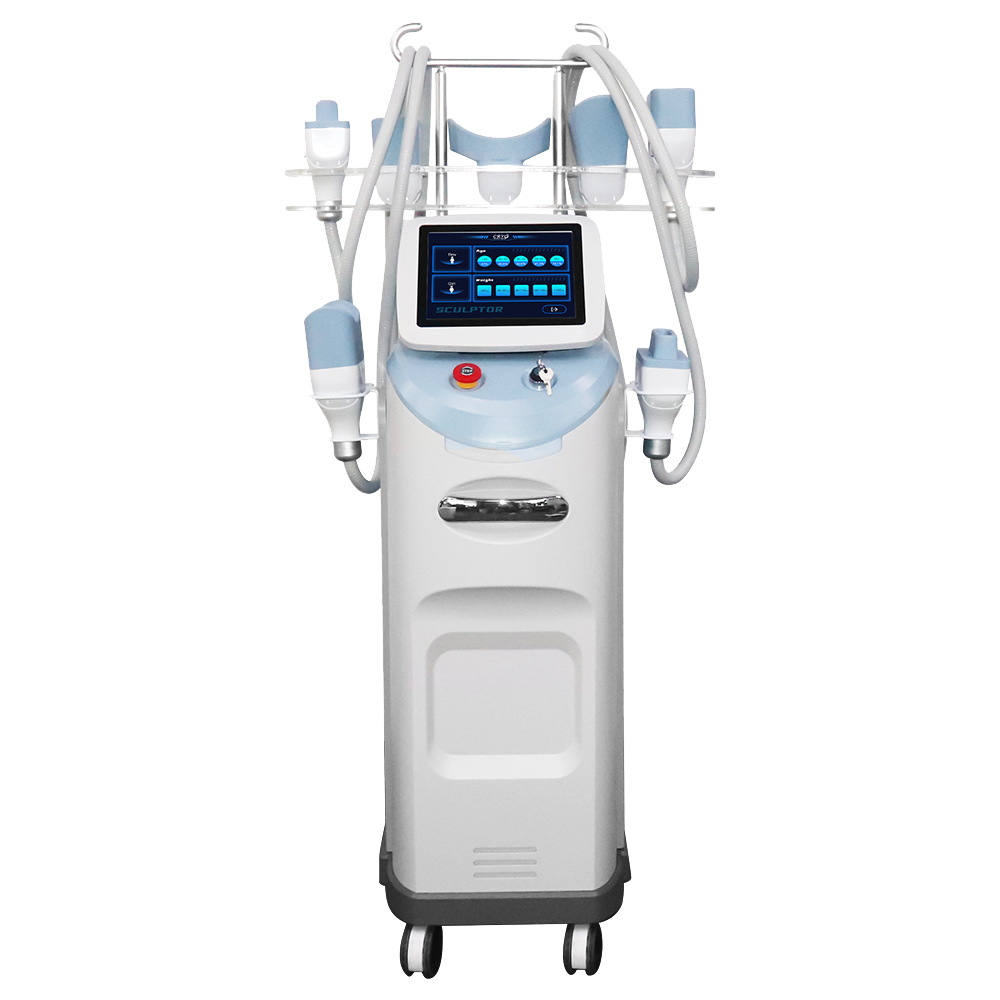

At Shefmon, we understand that professional aesthetic equipment is not only a product but a high-value investment for clinics, distributors, and medical aesthetic professionals. A machine may perform perfectly in the factory, but without a professional packaging process, it can be compromised during transportation. That is why our factory treats packaging as an essential part of manufacturing quality, not an afterthought. From internal protection design to outer case selection and final inspection, every step of our packaging process is engineered to ensure safety, stability, and reliability during global shipping.

1. Why Professional Packaging Matters in Our Factory

Aesthetic equipment contains precision electronic components, handpieces, cables, and sensitive control systems. During international transport, machines may face vibration, compression, drops, and long transit times. Our factory designs packaging to withstand these real-world logistics challenges.

1.1 Protecting Equipment Performance and Structure

Our goal is to ensure that every machine arrives exactly as it leaves our production line. Professional packaging prevents internal collision, deformation, loose components, and cosmetic damage, all of which can affect performance and customer satisfaction.

1.2 Reflecting Manufacturing Standards

Packaging is often the first physical interaction customers have with our equipment. A clean, organized, and reinforced packaging system reflects our factory’s attention to detail, professionalism, and commitment to long-term product reliability.

2. Pre-Packaging Preparation at Shefmon

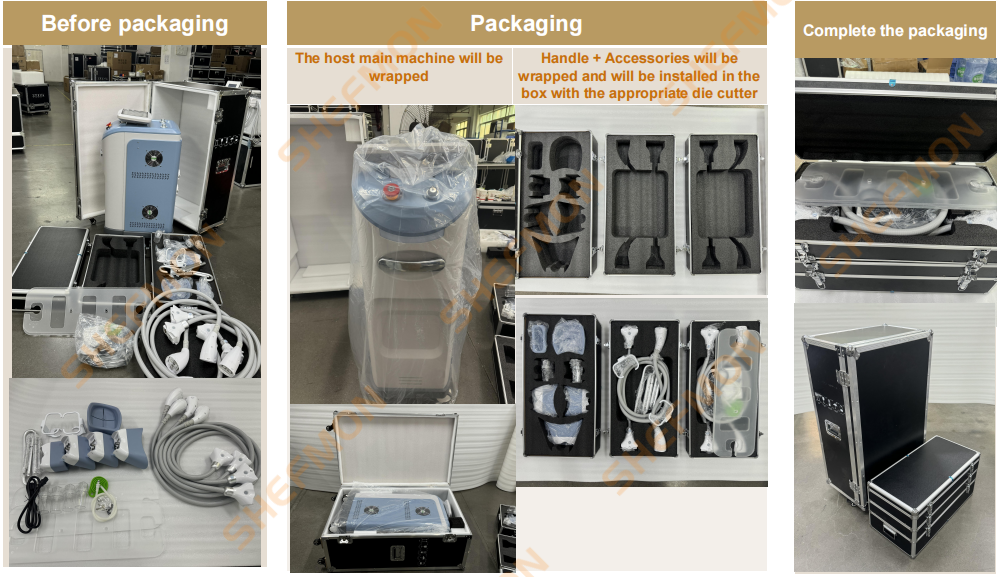

Before any machine is placed into a case or carton, our packaging process begins with structured preparation.

2.1 Component Arrangement and Verification

Each machine and its accessories are carefully arranged before packaging. This includes the main unit, handpieces, cables, tools, manuals, and protective accessories. Our team verifies completeness and checks for any visible issues to avoid missing or misplaced components.

2.2 Surface Protection Before Wrapping

To protect the exterior finish, all visible surfaces are covered with protective materials. This prevents scratches, dust contamination, or minor abrasions during handling and packing.

3. Internal Protection System Design

Internal protection is the core of our professional packaging process. It ensures that all components remain stable inside the package.

3.1 Customized Pearl Cotton Thickness

Our factory selects pearl cotton thickness based on the actual weight and structure of each machine. For heavier or more complex equipment, we use thicker cushioning to enhance shock absorption. This approach provides stronger protection compared to standard thin padding and significantly reduces impact damage during transport.

3.2 Custom Die-Cutting for Precise Fit

We use custom cutting dies specifically designed for each machine model. This allows the internal cushioning to match the exact shape of the equipment and accessories. Proper die-cutting ensures that components do not shift, collide, or press against each other during shipping.

3.3 Separate Fixation of Main Unit and Accessories

The main machine and accessories are packaged in separate, designated positions. Handles, cables, and tools are individually wrapped and secured to prevent friction or pressure against the main unit.

4. Aluminum Case Packaging Solution

For high-value aesthetic equipment, our factory uses reinforced aluminum cases as a premium packaging solution.

4.1 Reinforced Composite Panel Structure

Our aluminum cases are built with reinforced composite panels that offer exceptional load-bearing strength. The structure is strong enough to withstand heavy pressure during stacking and transportation, providing superior protection compared to standard packaging materials.

4.2 Secure Locking System

The locking mechanism on our aluminum cases requires deliberate rotation before locking, ensuring a tighter and more secure closure. This design reduces the risk of accidental opening and enhances overall transport safety.

5. Carton Box Packaging Options

In addition to aluminum cases, we also provide professional carton box packaging solutions depending on the machine type and shipping requirements.

5.1 Multi-Layer Carton Selection

Our factory selects five-layer or seven-layer carton boxes based on machine size, weight, and shipping distance. Thicker cartons provide improved shock absorption and structural stability during long-distance transportation.

5.2 Material Choices for Different Needs

We offer different carton materials, including corrugated paper for cost-effective solutions and kraft paper for enhanced water resistance and durability. This flexibility allows us to match packaging solutions to customer logistics needs.

6. Final Packaging and Quality Inspection

Before shipment, all packaged equipment goes through a final quality control stage.

6.1 Stability and Security Check

Our team checks internal stability by ensuring that no movement occurs inside the packaging. Proper fixation confirms that internal cushioning and die-cut designs are correctly applied.

6.2 Completion and Shipment Readiness

After verification, documentation such as manuals and warranty materials is placed securely inside the package. The packaging is then sealed, labeled, and prepared for shipment.

Conclusion

At Shefmon, a professional packaging process is an extension of our manufacturing philosophy. By combining structured preparation, customized internal protection, reinforced aluminum cases, and strict final inspections, our factory ensures that every aesthetic device is protected from the moment it leaves production until it reaches the customer. This comprehensive packaging system not only safeguards equipment performance but also reinforces trust, reliability, and long-term value for clinics and distributors worldwide.