Share optimized solutions, professional valve knowledge and industry news

Please enter the relevant terms or keywords you need to consult, and relevant articles will appear in the search results. If you can’t find the answer you need, please feel free to contact us and we will be happy to help. Or you can directly send an email to beauty@shefmon.com

Key Considerations for Evaluating a Beauty Equipment Supply System: Part 2

- shefmon

Our factory views a beauty equipment supply system as a combination of mechanical structure, electronic architecture, and user-facing components working together under real clinical conditions. In Part 2, we focus on two critical but often underestimated areas of supply system evaluation: power supply design and display system selection. These elements directly affect device performance, safety, operating stability, and long-term user experience. For distributors, clinics, and brand owners, understanding these factors is essential when assessing a supplier’s true engineering capability.

1. Power Supply as the Core of Functional Capability

In professional beauty equipment, the power supply is not a simple supporting component. It directly determines what functions a device can achieve and how reliably those functions perform over time.

1.1 Power Output and Functional Boundaries

Different beauty instruments require different power levels to operate effectively. At our factory, we classify power supply systems based on functional demands.

High-power power supplies are designed for energy-intensive applications such as laser hair removal, radiofrequency tightening, and deep thermal therapies. These treatments require stable, high-energy output to penetrate tissue layers safely and effectively. In contrast, low-power power supplies are suitable for lightweight care devices such as ultrasonic cleansers, infusion systems, and basic skin care equipment, where gentle and consistent output is more important than peak energy.

A professional supply system ensures that the power supply is correctly matched to the intended treatment functions rather than relying on generic, one-size-fits-all solutions.

1.2 Voltage and Current Output Matching

Beauty devices integrate multiple modules, each with distinct electrical requirements. RF modules often require high-frequency, high-voltage output, while control panels, sensors, and logic boards rely on stable low-voltage DC power.

Our factory designs power supplies with multiple dedicated outputs, allowing each component to receive precisely matched voltage and current. This approach ensures stable operation, prevents overload, and avoids functional interference between modules, especially during long treatment sessions.

1.3 EMC Certification and Electromagnetic Stability

Electromagnetic compatibility is a key consideration in professional power supply selection. EMC-certified power supplies reduce electromagnetic interference generated internally, protecting the accuracy of energy output in modules such as RF, laser, and phototherapy systems.

At the same time, EMC compliance improves resistance to external interference from other electrical equipment commonly found in salons and clinics. This ensures stable performance, consistent treatment effects, and enhanced operational safety in real-world environments.

2. Display System as a Key Interface Component

The display is the primary interface between the operator and the device. Its quality affects usability, visual clarity, appearance design, and system reliability.

2.1 Screen Size and Operating System Adaptation

Screen size directly determines operating system layout and user interaction logic. Smaller displays, typically between 4.3 and 8 inches, are well suited for portable or handheld devices where compactness is a priority. Larger screens, ranging from 10.4 to 18.5 inches, are designed for fixed professional equipment, providing clear visualization, intuitive controls, and better workflow efficiency.

At shefmon, screen size selection is closely aligned with UI design, resolution standards, and hardware layout. Mismatched screen size and software design can lead to crowded interfaces, blurred text, poor touch accuracy, and a compromised user experience.

2.2 Screen Type: Capacitive vs. Resistive

Capacitive screens are widely used in modern professional beauty equipment. They support multi-touch finger operation, provide high sensitivity, and are ideal for frequent interaction. Common sizes include 5-inch, 7-inch, 10.4-inch, 13.3-inch, 15.6-inch, and 18.5-inch formats. Capacitive screens also support customization such as special shapes or curved designs, enabling stronger brand differentiation.

Resistive screens rely on pressure-based input and are typically used in industrial or precision-control environments. While less responsive to finger touch, they can be suitable for specific embedded applications where stylus operation or high environmental tolerance is required.

2.3 Viewing Angle and Visual Performance

Viewing angle has a direct impact on operational comfort. Ordinary display technologies, such as TN panels, typically offer viewing angles between 90° and 120°. When viewed from slight angles, images may turn white, colors distort, and text becomes unclear, negatively affecting operation accuracy.

IPS capacitive displays, which we prioritize at our factory, offer full viewing angles up to 178° both horizontally and vertically. Colors, brightness, and contrast remain stable even when viewed from the side or at an angle, making them ideal for multi-operator environments and professional treatment rooms.

3. Screen Quality, Stability, and Failure Risk

Beyond specifications, screen sourcing strategy plays a critical role in long-term reliability.

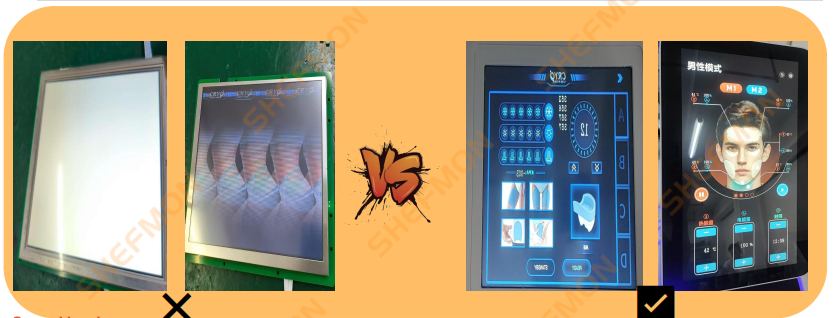

3.1 New Screens vs. Refurbished Screens

Some suppliers use refurbished or second-hand screens to reduce costs. These screens often suffer from panel aging, backlight attenuation, bad pixels, and worn touch layers. While they may function in the short term, failure rates increase significantly under continuous operation and high temperatures, leading to black screens, touch failure, and increased downtime.

Our factory exclusively uses newly manufactured screens. All key components, including the panel, backlight, and touch layer, are unused and fully tested. This ensures fast pixel response, stable touch sensitivity, and a backlight lifespan of at least 50,000 hours, reducing failure risks at the source.

3.2 Supplier Selection and Consistency Control

Display quality is also influenced by supplier selection. Industry-leading display suppliers offer mature production processes, strict quality control, and stable raw material sourcing. Batch-to-batch parameter deviation is tightly controlled, typically within 10%, ensuring consistent performance across production runs.

In contrast, small or poorly managed suppliers often show inconsistent materials, weak process control, and higher failure rates, especially under extreme temperature or humidity conditions. For professional beauty equipment, such instability directly translates into higher maintenance costs and reputational risk.

Conclusion

In a professional beauty equipment supply system, power supply design and display system selection are decisive factors that define performance boundaries, operational stability, and user experience. At shefmon, we treat these components as core engineering decisions rather than cost-driven compromises. By matching power supply architecture to functional requirements, ensuring EMC compliance, and selecting high-quality display systems with proven reliability, we build equipment that performs consistently in real clinical environments. These considerations form a critical part of evaluating a supplier’s true technical strength and long-term value.