Share optimized solutions, professional valve knowledge and industry news

Please enter the relevant terms or keywords you need to consult, and relevant articles will appear in the search results. If you can’t find the answer you need, please feel free to contact us and we will be happy to help. Or you can directly send an email to beauty@shefmon.com

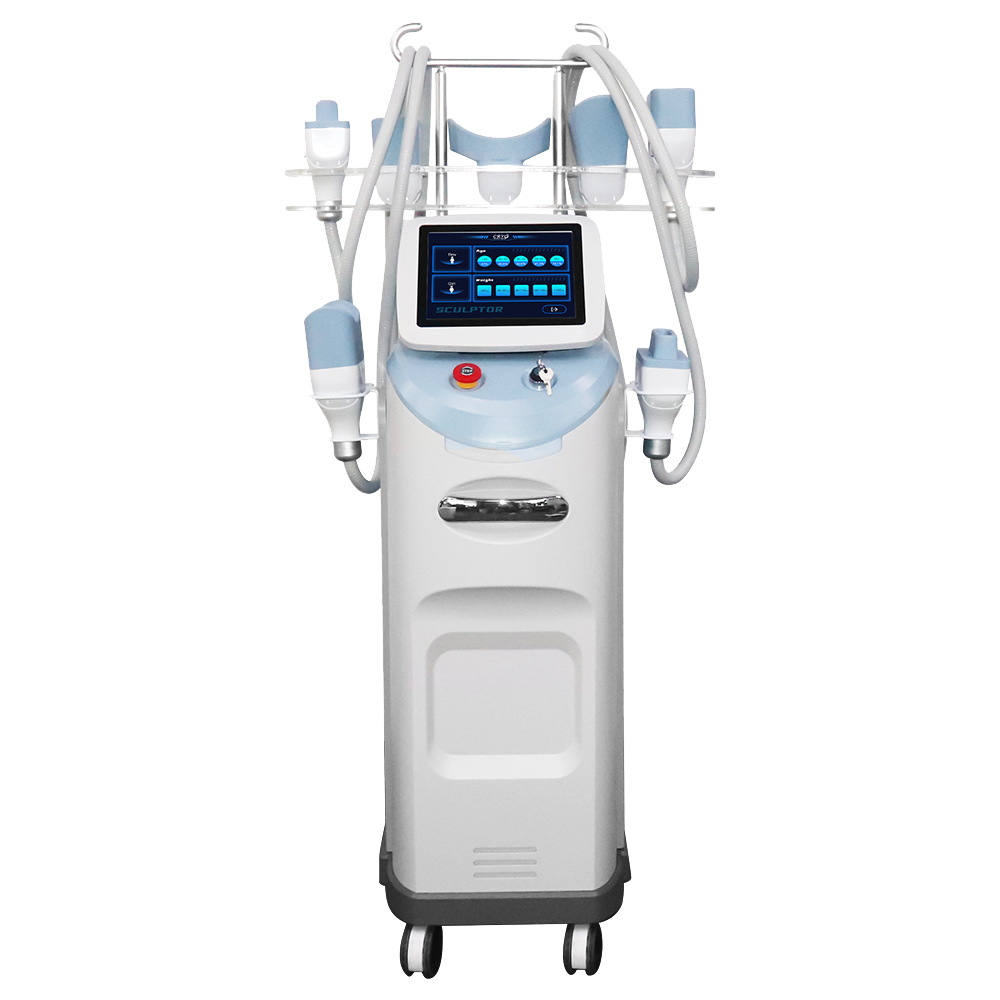

How Does Warehouse Organization Affect Beauty Device Manufacturing?

- shefmon

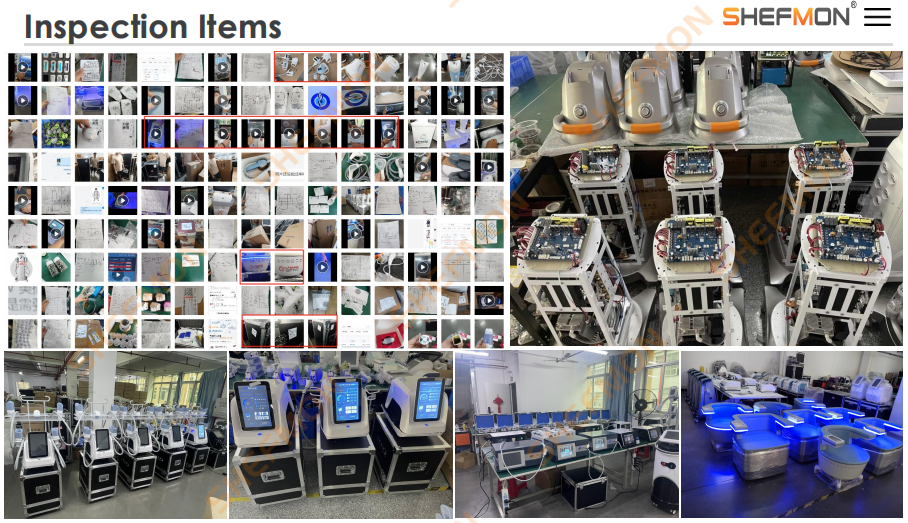

In beauty device manufacturing, product quality is not determined solely on the production line. At our factory, warehouse organization plays a crucial role in ensuring consistency, safety, efficiency, and traceability throughout the entire manufacturing process. From raw material storage to finished equipment dispatch, a well-structured warehouse system directly impacts production accuracy, delivery timelines, and overall product reliability. Understanding how warehouse organization affects beauty device manufacturing helps buyers and partners evaluate a factory’s true operational strength.

1. The Role of Warehouse Organization in Manufacturing

A professional warehouse is not just a storage space; it is an active part of the manufacturing ecosystem. Proper organization ensures that materials and products move smoothly through each production stage without confusion or delay.

1.1 Supporting Stable Production Flow

In beauty device manufacturing, production relies on timely access to components such as electronic boards, handpieces, cables, shells, and accessories. A well-organized warehouse ensures that materials are clearly classified, accurately labeled, and easily accessible. This minimizes production interruptions and prevents delays caused by misplaced or incorrectly stored components.

1.2 Reducing Operational Errors

Disorganized storage increases the risk of using the wrong parts, outdated components, or unapproved materials. By implementing standardized warehouse zones and clear identification systems, our factory reduces human error and ensures that every production batch uses the correct materials.

2. Raw Material and Component Management

The foundation of any beauty device lies in the quality of its raw materials and components. Warehouse organization directly affects how these materials are preserved and managed.

2.1 Clear Classification and Zoning

Our warehouse divides raw materials, electronic components, mechanical parts, and accessories into dedicated zones. Each category is stored separately according to its characteristics, such as sensitivity to humidity, temperature, or static electricity. This structured classification protects material integrity and supports consistent manufacturing quality.

2.2 Traceability and Batch Control

Organized warehousing allows precise tracking of materials by batch number and production date. This traceability is essential for quality control, especially if post-production inspections or after-sales analysis are required. It also supports compliance with international manufacturing and safety standards.

3. Impact on Production Efficiency

Warehouse organization directly influences how efficiently beauty devices are manufactured.

3.1 Faster Material Picking and Replenishment

With a standardized layout and clear storage logic, warehouse staff can quickly locate and deliver materials to the production line. This reduces waiting time, prevents bottlenecks, and allows assembly teams to focus on precision work rather than logistics issues.

3.2 Inventory Accuracy and Planning

Accurate inventory management prevents overstocking or material shortages. A well-managed warehouse enables better production planning, helping the factory align manufacturing schedules with order volumes and delivery commitments.

4. Quality Control and Risk Prevention

Beauty devices are precision instruments that require strict quality control. Warehouse organization plays a preventive role in avoiding quality risks before production even begins.

4.1 Preventing Damage and Contamination

Sensitive components such as circuit boards and optical parts must be stored in clean, controlled environments. Organized storage with appropriate protection reduces the risk of dust contamination, moisture exposure, or physical damage that could affect device performance.

4.2 Supporting Pre-Production Inspection

Before materials enter the production line, warehouse organization allows quality control teams to conduct inspections efficiently. Proper labeling and storage make it easier to verify specifications, appearance, and compliance, ensuring that only approved components are used.

5. Safety and Compliance in the Warehouse

A professional warehouse system prioritizes safety for both personnel and products.

5.1 Clear Signage and Safety Zones

Warning signs, safety markings, and clearly defined walkways reduce the risk of accidents. Fire safety systems and regular drills further protect staff, equipment, and inventory, ensuring uninterrupted manufacturing operations.

5.2 Compliance with Industry Standards

Organized warehouses support compliance with manufacturing and export regulations. Clear documentation, controlled access, and standardized storage conditions help meet the expectations of global distributors and regulatory bodies.

6. Management of Finished Equipment

Warehouse organization continues to play a vital role even after manufacturing is complete.

6.1 Secure Storage Before Shipment

Finished beauty devices are stored in designated areas separate from raw materials. This prevents accidental damage, mixing, or confusion before packaging and shipment. Proper spacing and stacking rules protect equipment appearance and functionality.

6.2 Coordination with Packaging and Logistics

An organized warehouse allows seamless coordination between production, packaging, quality inspection, and loading teams. Machines move efficiently from final inspection to packaging and then to shipment preparation, reducing handling time and delivery risks.

7. Impact on Delivery and Customer Satisfaction

Ultimately, warehouse organization affects how customers experience the product.

7.1 On-Time Delivery Performance

Efficient warehouse management ensures that finished products are located quickly and prepared for shipment without delay. This improves on-time delivery rates and strengthens customer trust.

7.2 Long-Term Brand Reliability

Consistent warehouse practices contribute to stable product quality, fewer shipping issues, and smoother after-sales service. For distributors and clinics, this reliability is a key factor in building long-term partnerships with a manufacturer.

Conclusion

Warehouse organization is a critical but often overlooked factor in beauty device manufacturing. At Shefmon, a standardized, clean, and well-managed warehouse system supports every stage of production, from raw material handling to finished equipment delivery. By improving efficiency, reducing risks, enhancing quality control, and ensuring safety, professional warehouse organization directly contributes to manufacturing excellence. For buyers and partners, evaluating a factory’s warehouse system provides valuable insight into its true capability, reliability, and commitment to quality.