Share optimized solutions, professional valve knowledge and industry news

Please enter the relevant terms or keywords you need to consult, and relevant articles will appear in the search results. If you can’t find the answer you need, please feel free to contact us and we will be happy to help. Or you can directly send an email to beauty@shefmon.com

How Does An Experienced Beauty Machine Factory Manage Its Production?

- shefmon

As an experienced beauty machine manufacturer, Shefmon understands that stable quality and reliable delivery are the foundation of long-term cooperation with global partners. Production management is not limited to assembling machines; it is a systematic process that integrates organizational structure, standardized procedures, skilled workers, advanced equipment, and continuous process optimization. Through years of industry experience, our factory has built a mature production management system designed to ensure consistency, safety, and scalability across all product lines.

1. Production Management System at Shefmon

1.1 Clear Department Division

Shefmon’s production management begins with a clearly defined departmental structure. The factory operates with independent yet closely coordinated departments, including the Spare Parts Warehouse, Production Department, Shipping Department, After-Sales Department, and R&D Department. Each department has well-defined responsibilities, allowing materials, production schedules, quality inspection, logistics, and technical support to operate efficiently without overlap or confusion. This structure significantly reduces internal delays and quality risks.

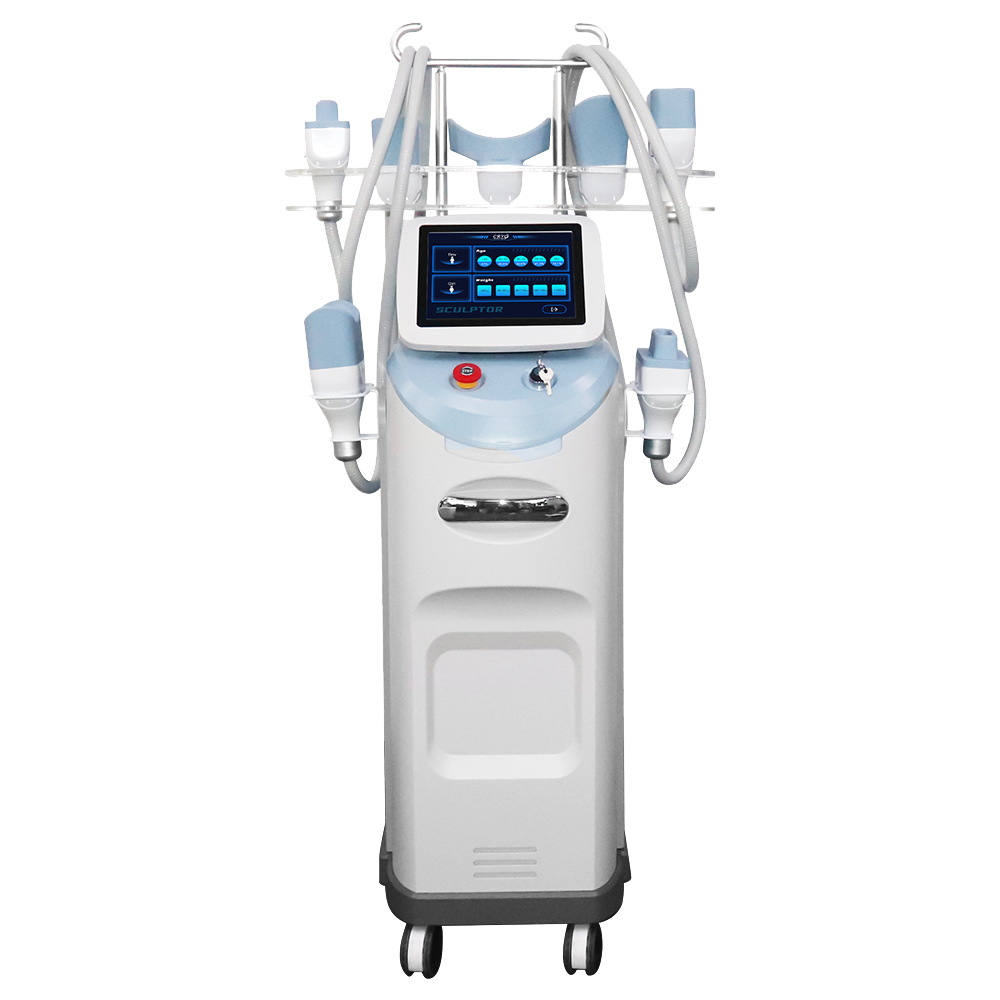

1.2 Dedicated Production Lines

To ensure stable output and on-time delivery, Shefmon assigns dedicated production lines to different product series. By separating production lines based on product structure and technology, Shefmon avoids cross-interference between models and improves consistency. This approach is particularly important for complex beauty machines that require precise assembly and strict quality control.

1.3 Fast and Exclusive R&D Integration

Shefmon integrates R&D closely with production management. New product designs are developed rapidly with exclusive structures and functions, reducing market duplication. During development, production feasibility and assembly efficiency are evaluated early, ensuring that new designs can be smoothly transferred into mass production without compromising quality.

2. Workshop Organization and Manufacturing Capability

2.1 Specialized Workshop Layout

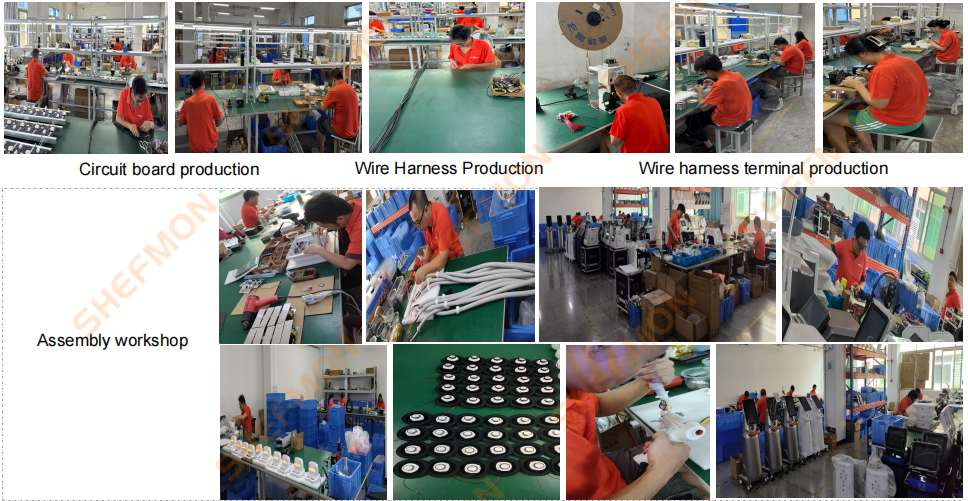

Shefmon’s factory workshop is divided into specialized production areas, including circuit board production, wire harness production, wire harness terminal processing, and final assembly workshops. This separation ensures that each process operates in a controlled environment, reducing contamination, interference, and handling errors.

2.2 Process-Oriented Workflow Design

Each workshop follows a clearly defined workflow that aligns with Shefmon’s production management standards. Materials and semi-finished components move in a logical sequence, allowing managers to track progress and identify potential issues at an early stage.

3. Workforce Management and Experience

3.1 Skilled Production Team

Shefmon employs more than 50 production workers, with an average industry experience of over five years. This experienced workforce is familiar with the structural and electrical characteristics of beauty machines, enabling accurate assembly and stable quality output.

3.2 Training and Skill Standardization

Production management at Shefmon emphasizes regular training and skill standardization. Workers are trained to follow updated operating procedures, technical drawings, and safety requirements. This ensures consistency in assembly quality even as production volumes increase.

4. Standard Operating Procedures and Safety Control

4.1 Detailed SOP Documentation

Shefmon has established comprehensive standard operating procedures covering critical production steps. For example, detailed operation instructions for double-headed ultrasonic devices emphasize correct wiring order and component matching to prevent circuit board damage. Clear motherboard layout and fan installation diagrams ensure firm assembly and proper heat dissipation.

4.2 Electrical and Power Safety Standards

Strict power supply and wiring standards are enforced throughout production. SOPs clearly define voltage requirements, power socket specifications, fuse ratings, and wire color standards. These measures effectively reduce risks such as reverse connection, overheating, and electrical failure.

5. Production Equipment and Technical Support

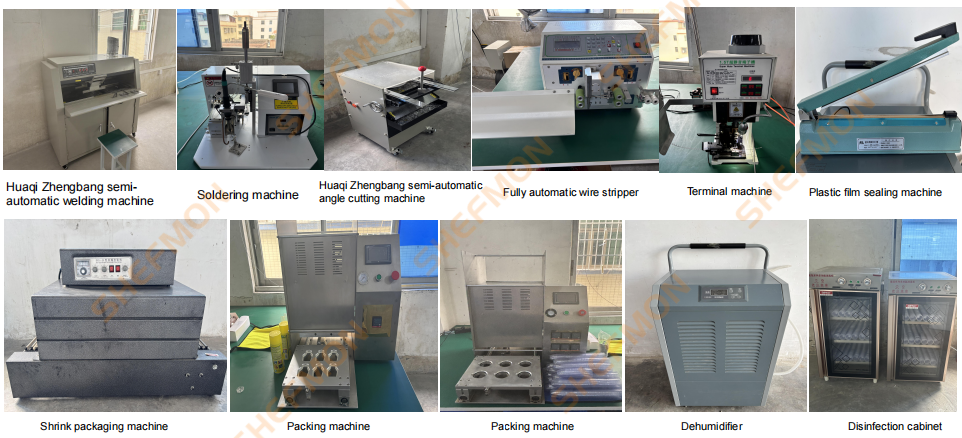

5.1 Professional Manufacturing Machines

Shefmon equips its production lines with professional machinery, including semi-automatic welding machines, soldering machines, automatic wire strippers, terminal machines, and packaging equipment. These machines improve production accuracy while reducing reliance on manual variability.

5.2 Environmental and Packaging Control

Supporting equipment such as dehumidifiers and disinfection cabinets help maintain stable production conditions. Finished products are sealed, shrink-wrapped, and packed using standardized processes to ensure safety during storage and transportation.

6. Standardized Production Process Control

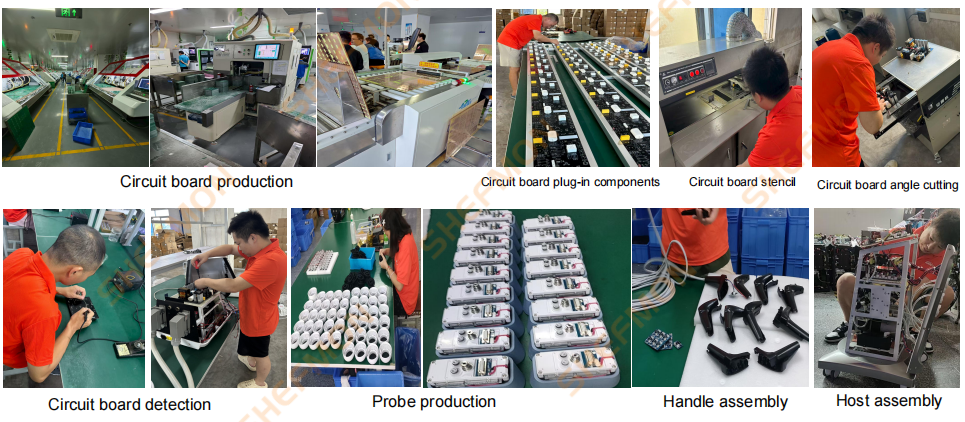

6.1 Structured Manufacturing Flow

Shefmon’s production process follows a structured sequence, including circuit board production, component plug-in, stencil processing, angle cutting, circuit board testing, probe production, handle assembly, and final host assembly. Each stage includes inspection points to ensure defects are identified early.

6.2 Integrated Quality Inspection

Quality inspection is embedded into the production process rather than conducted only at the final stage. This reduces rework rates and ensures that only qualified components proceed to the next step.

7. Process Optimization and Craft Management

7.1 Glue Application and Sealing Control

Glue application is carefully managed to ensure part fixation and auxiliary sealing. Shefmon controls glue quantity accuracy, curing integrity, and sealing performance using aging-resistant silicone materials. This prevents loosening, abnormal noise, and leakage during long-term use.

7.2 Cable Management and Structural Optimization

Wire bundling is standardized using high-quality nylon cable ties with controlled spacing. Structural optimization focuses on water and electricity separation, modular design, and organized wiring paths, improving safety and ease of maintenance.

7.3 Surface Treatment and Circuit Board Soldering

Spray painting and controlled drying processes protect the appearance and corrosion resistance of machine housings. Circuit board soldering quality is ensured through machine welding and AOI visual inspection, significantly reducing false soldering and circuit failures.

Conclusion

At Shefmon, production management is a comprehensive system that combines organizational clarity, skilled labor, standardized procedures, advanced equipment, and continuous process optimization. By controlling every detail from workshop layout and wiring standards to structural design and quality inspection, Shefmon ensures stable production quality, reliable delivery, and long-term product performance. This systematic approach enables Shefmon to meet the demands of global beauty device partners with consistency and confidence.