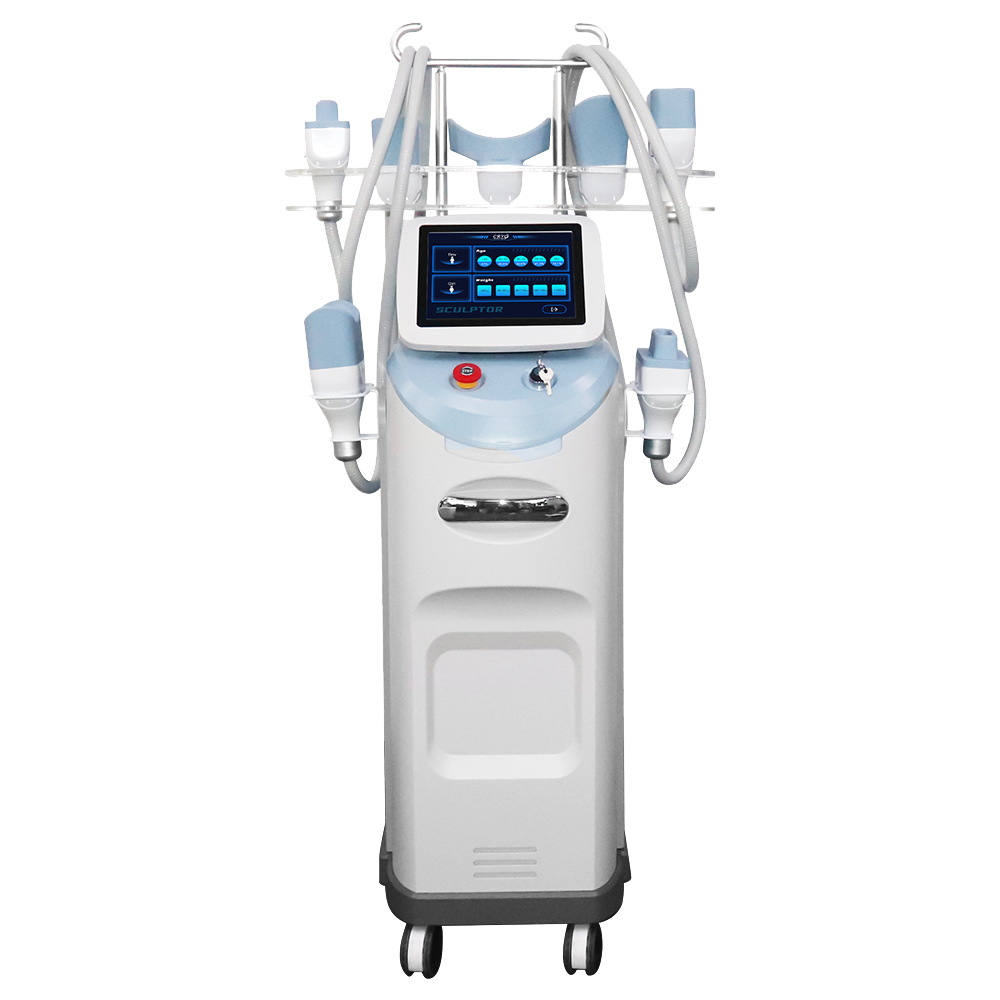

At shefmon, a professional beauty equipment supply system is defined by how reliably energy, control, and execution subsystems work together under continuous clinical operation. In Part 4, we focus on two deeply technical yet decisive areas: the host gas system and the host circuit system. These systems determine response speed, operational stability, safety margins, and long-term durability—especially for advanced applications such as cryolipolysis and ice sculpting that require hours of uninterrupted, precisely controlled performance.

1. Host Gas System: Stability, Precision, and Safety

The gas system functions as a dynamic power delivery network for pneumatic actions and auxiliary cooling. At our factory, we design the gas system as a closed, protected loop to avoid pressure instability and contamination-related failures.

1.1 Air Pump as the Pneumatic Power Source

We use high-stability air pumps with adjustable flow and a controlled pressure range (typically 0.4–0.6 MPa). These pumps are engineered for long-term, low-noise operation, making them suitable for extended clinical sessions.

A stable air source prevents execution lag caused by pressure fluctuations—such as inconsistent clamping force or uneven airflow-assisted cooling. Low-noise design protects operator concentration during precision procedures, which is critical in lengthy cryolipolysis treatments.

1.2 Multi-Stage Filtration for Gas Purity

Gas purity is fundamental to protecting downstream precision components. Our gas systems employ multi-stage filtration, combining a pre-coarse filter with a high-precision filter element capable of removing particles down to 0.3 μm, as well as moisture and oil contaminants.

Automatic drainage reduces manual maintenance while preventing moisture accumulation. Clean gas protects solenoid valve cores from rust, prevents oil fouling on sensor probes, and avoids dust blockage in gas lines—eliminating failures such as valve jamming or false sensor alarms at the source.

1.3 SMC Solenoid Valves for Fast and Reliable Control

For critical switching control, we integrate original Japanese SMC solenoid valves. With a response speed of approximately 5 ms, IP65 sealing, and a lifecycle exceeding one million cycles, these valves are designed for high-frequency operation.

As the “commander” of the gas circuit, fast response ensures immediate execution of pneumatic functions, such as rapid start/stop of airflow-assisted refrigeration. High sealing prevents pressure loss, while long service life reduces maintenance frequency and downtime.

1.4 Air Pressure Sensors for Real-Time Protection

High-precision air pressure sensors continuously monitor gas pressure and feed data back to the control system. Adjustable thresholds enable overpressure and underpressure alarms.

This real-time monitoring provides active protection: pressure is released when levels are too high to avoid overload damage, and alerts prompt replenishment when pressure drops to prevent functional failure. Stable pressure control is essential for uniform jet cooling and consistent pneumatic assistance.

2. Host Circuit System: The Intelligence Behind Execution

While the gas system delivers force, the circuit system provides intelligence and coordination. At our factory, we independently design and integrate the core electronics to ensure precise timing, protection, and system-level compatibility.

2.1 Motherboard as the Central Control Unit

Our independently developed motherboard integrates the CPU, temperature control chips, driver chips, and multiple interfaces connecting handles, gas circuits, cooling systems, and sensors. With a response speed of ≤10 ms, it supports real-time data interaction across all subsystems.

When the handle LCD issues an instruction, the motherboard synchronously adjusts air pump pressure, refrigeration power, and cooling fan speed. Independent design ensures full interface matching and avoids delays or failures caused by compatibility gaps common in outsourced control boards.

2.2 Power Supply for Global Stability

The power supply is engineered with wide voltage input (AC 100–240 V) and provides multiple stable DC outputs such as 5 V, 12 V, and 24 V with ±2% accuracy. Integrated overvoltage, overcurrent, and short-circuit protection safeguards sensitive components.

Low temperature rise (≤50 °C) supports long-term stability in enclosed environments. Wide voltage adaptability ensures consistent operation across different regional power grids, preventing unexpected shutdowns during extended treatments.

2.3 Capacitors for Voltage Regulation and Noise Immunity

We select high-frequency, low-resistance electrolytic capacitors with high withstand voltage (up to 1500 V) and large capacity (around 200 μF). With capacitance deviation ≤5% and a lifespan ≥10,000 hours, these components stabilize the DC bus and filter low-frequency ripple.

On the motherboard, ceramic capacitors absorb high-frequency interference, protecting sensor data transmission from distortion—such as false air pressure alarms. High temperature tolerance ensures reliability under sustained thermal stress.

2.4 Thyristors for High-Power Control

High-power thyristors are used for intelligent power control. With continuous current capacity up to 500 A, switching response ≤35 μs, and withstand voltage ≥2200 V, they enable precise regulation through phase-angle adjustment.

Integrated overtemperature protection automatically shuts down the device if junction temperature exceeds safe limits, preventing component burnout and system-wide failure.

2.5 AC Filters for Electromagnetic Protection

Multi-stage EMI filtering—using common-mode inductors and differential capacitors—provides insertion loss ≥40 dB across 100 kHz to 10 MHz. This blocks grid-borne noise such as surge spikes from nearby equipment.

At the same time, grounded filter enclosures suppress electromagnetic radiation generated internally, preventing interference with handle LCD displays and sensor signals, and ensuring stable, interference-free operation.

3. Supplier Control and Component Verification

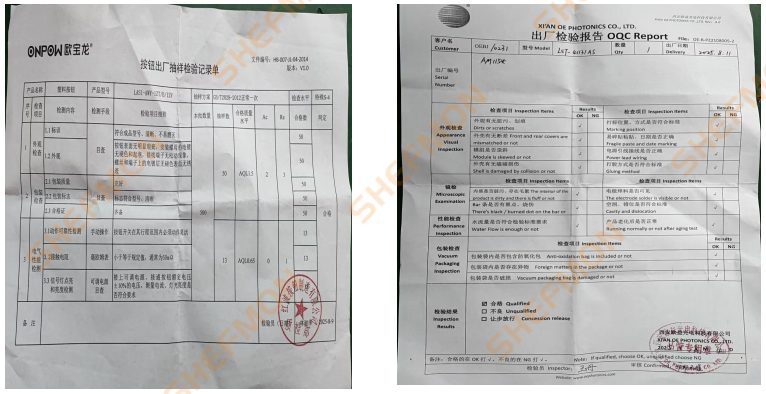

At our factory, supplier capability is part of the supply system. We manage mold making and injection molding production in coordination with qualified partners to ensure dimensional accuracy and material consistency. Every critical component is validated through inspection reports before integration, forming a documented quality baseline.

Conclusion

In a professional beauty equipment supply system, the host gas system and circuit system determine whether advanced functions can be executed safely, precisely, and continuously. At our factory, we engineer these systems as tightly integrated, protected networks—combining stable pneumatic power, intelligent electronic control, and robust component selection. This approach minimizes failure risk, enhances treatment consistency, and delivers long-term operational reliability for demanding clinical environments.