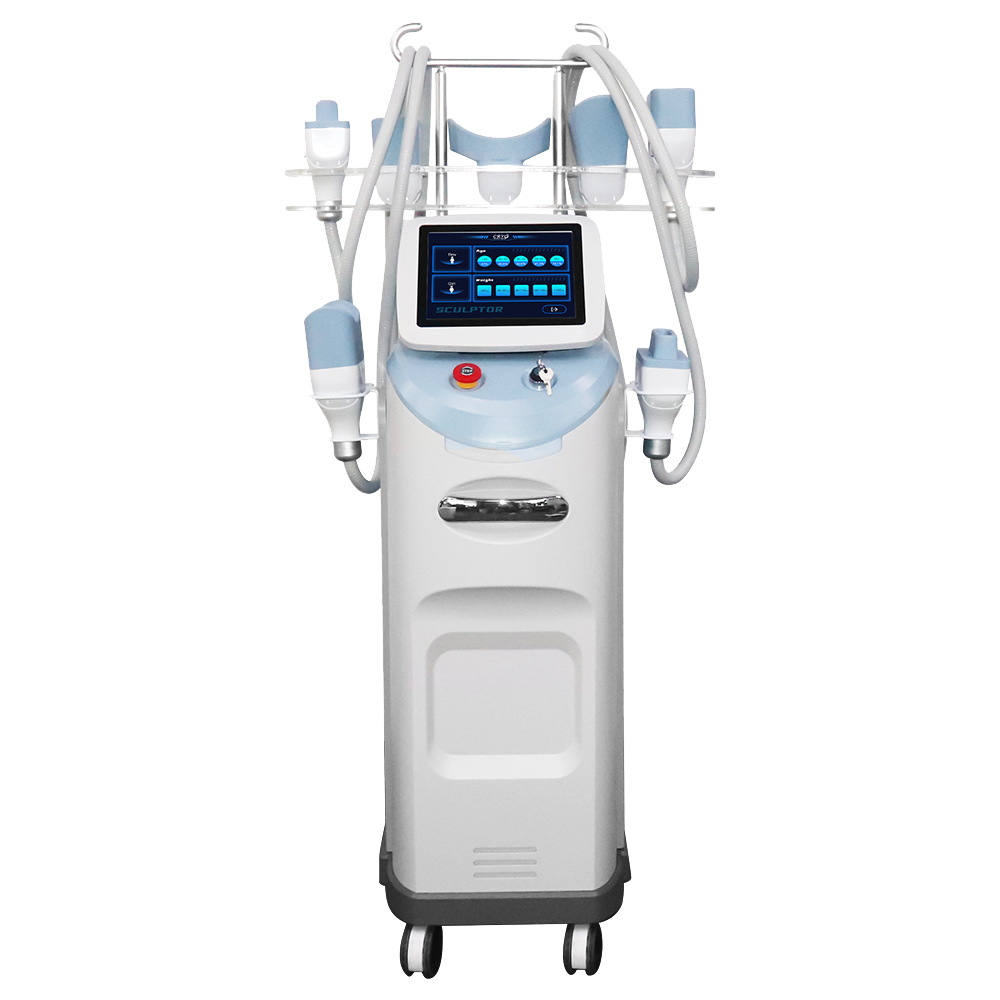

In a professional beauty equipment supply system, performance is ultimately delivered at the point of treatment. In Part 3, we focus on two critical elements that directly affect treatment accuracy, operator experience, and long-term reliability: the treatment handle and the host cooling system. At our factory, these components are engineered as integrated functional systems rather than isolated parts. Their design, materials, and internal structure play a decisive role in treatment safety, consistency, and operational continuity, especially for energy-intensive procedures such as cryolipolysis.

1. Treatment Handle as a Functional Extension of the System

The handle is not a simple accessory. It is the primary interface between the device, the operator, and the client, making it one of the most important components in the supply system.

1.1 Appearance Design and Functional Uniqueness

Our new cryolipolysis handle adopts an independently developed appearance design and is manufactured through injection molding rather than generic assembly. The unique shape distinguishes it clearly from common market handles and reinforces its dedicated purpose for cryolipolysis treatments.

We apply a premium liquid over-mold coating instead of traditional solid glue encapsulation. This process delivers a refined surface finish that meets the aesthetic standards of high-end clinical environments while also improving durability. The visual and tactile quality of the handle communicates professionalism and purpose at first contact.

1.2 Ergonomics and Operator Efficiency

Ergonomics is essential for long treatment sessions. Our handle design follows professional grip habits, ensuring comfort during extended use and reducing hand fatigue. This allows operators to maintain precise control throughout lengthy cryolipolysis procedures.

An integrated LCD screen and direct control interface are built into the handle. This enables operators to adjust parameters directly at the point of use, minimizing the need to look away from the treatment area or repeatedly interact with the main unit. The result is improved workflow efficiency and greater operational accuracy.

1.3 Refrigeration Integration and Maintenance Design

Our cryolipolysis handle is lighter and thinner than traditional designs, making it suitable for detailed sculpting tasks such as hollowing and contour refinement. Integrated molding eliminates frequent plugging and unplugging, reducing wear on connectors and lowering failure risk.

The handle is designed to be waterproof, preventing seepage from melted ice during treatment and allowing stable operation in humid environments. Its modular structure enables easy disassembly and maintenance, ensuring that routine servicing does not interrupt clinical operations.

1.4 Advantages of the Liquid Over-Mold Process

The liquid over-mold coating used in our handle costs significantly more than solid rubber encapsulation, but it delivers measurable benefits. Compared with solid glue, which is prone to scratches and poor elastic recovery, the liquid coating offers a softer, more resilient grip suitable for prolonged use.

Weight consistency is another critical advantage. Cryolipolysis requires precise and uniform force control. Our process ensures consistent handle weight across production batches, enabling uniform treatment pressure. In addition, production speed is significantly higher, supporting large-scale manufacturing without compromising quality.

1.5 Interface Stability and Connection Security

During long cryolipolysis sessions, handle stability is essential. Our handle connector features a lockable interface that prevents accidental disconnection caused by movement or vibration.

This locking mechanism reduces error alarms, prevents unexpected shutdowns, and ensures uninterrupted treatment. For procedures that may last several hours, connection stability is critical to maintaining treatment continuity and client safety.

1.6 Heat Dissipation and Cooling Efficiency

The handle integrates a larger internal cooling water capacity and increased flow rate, enabling faster heat transfer and improved cooling speed. Rapid refrigeration is essential in cryolipolysis, where precise temperature control directly affects treatment effectiveness.

Improved heat dissipation prevents cooling attenuation caused by overheating and ensures stable low-temperature performance during continuous operation.

1.7 Temperature Control Protection System

Cryolipolysis is highly sensitive to temperature variations. Our handle incorporates a precise temperature control protection system that prevents over-cooling, which could cause tissue damage, and over-heating, which could shorten handle lifespan.

The system adapts refrigeration parameters to different ice qualities, ensuring safety, improving treatment consistency, and protecting internal cryogenic materials from thermal stress.

2. Host Cooling System as the Foundation of Stability

The host cooling system supports the handle and determines whether the device can operate continuously under demanding conditions.

2.1 High-Flow Diaphragm Pump Design

Our host system uses a DP-150 diaphragm pump with a flow rate of 5 L/min. The diaphragm structure provides stable operation and strong resistance to low-temperature corrosion.

The high flow rate ensures that heat generated at the handle is rapidly returned to the main unit for dissipation, increasing cooling speed by more than 30% compared to ordinary pumps. This design prevents blockages and leakage in ice-water mixed environments, supporting uninterrupted long-term operation.

2.2 Large-Capacity Transparent Water Tank

The host is equipped with a large, blue transparent water tank. Its capacity reduces the frequency of water refills and supports long cryolipolysis sessions without interruption.

Transparency allows operators to easily monitor water levels, preventing sudden heat dissipation failure caused by insufficient coolant. This is especially important during large-area treatments that may last several hours.

2.3 Enhanced Heat Dissipation Area and Silent Fan

The cooling water discharge system is designed with a heat dissipation area that is 50% larger than traditional layouts and is paired with a high-speed silent fan.

This combination increases overall heat dissipation efficiency by approximately 40%, ensuring that the circulating water re-entering the handle remains at a lower temperature. The silent fan design minimizes noise, allowing operators to maintain focus during precision procedures.

2.4 Condenser as the Thermal Endpoint

The condenser functions as the final heat transfer terminal in the cooling system. By efficiently releasing accumulated heat to the external environment, it prevents thermal buildup throughout the circulation loop.

This ensures low-temperature stability for both the host and the handle, even in high-ambient-temperature environments, maintaining consistent cooling performance throughout extended treatments.

Conclusion

In a professional beauty equipment supply system, the handle and host cooling system determine whether advanced technology can be delivered safely and consistently in real clinical use. At our factory, these components are engineered as integrated systems that prioritize ergonomics, thermal stability, operational continuity, and long-term reliability. By controlling every structural, material, and functional detail, we ensure that treatment performance remains stable under demanding conditions, providing lasting value for clinics, operators, and clients alike.