Share optimized solutions, professional valve knowledge and industry news

Please enter the relevant terms or keywords you need to consult, and relevant articles will appear in the search results. If you can’t find the answer you need, please feel free to contact us and we will be happy to help. Or you can directly send an email to beauty@shefmon.com

Key Considerations for Evaluating a Beauty Equipment Supply System: Part 1

- shefmon

Shefmon believe that a professional beauty equipment supply system is the foundation of long-term product reliability, safety, and scalability. Beyond appearance and pricing, the true strength of a supplier lies in how its supply system is structured, how materials are selected, and how core components are engineered to withstand real clinical usage. In Part 1 of this series, we explain how our factory builds and evaluates a supply system through three critical dimensions: composition structure transparency, machine enclosure materials, and core PCB engineering.

1. Composition Structure Transparency in Our Supply System

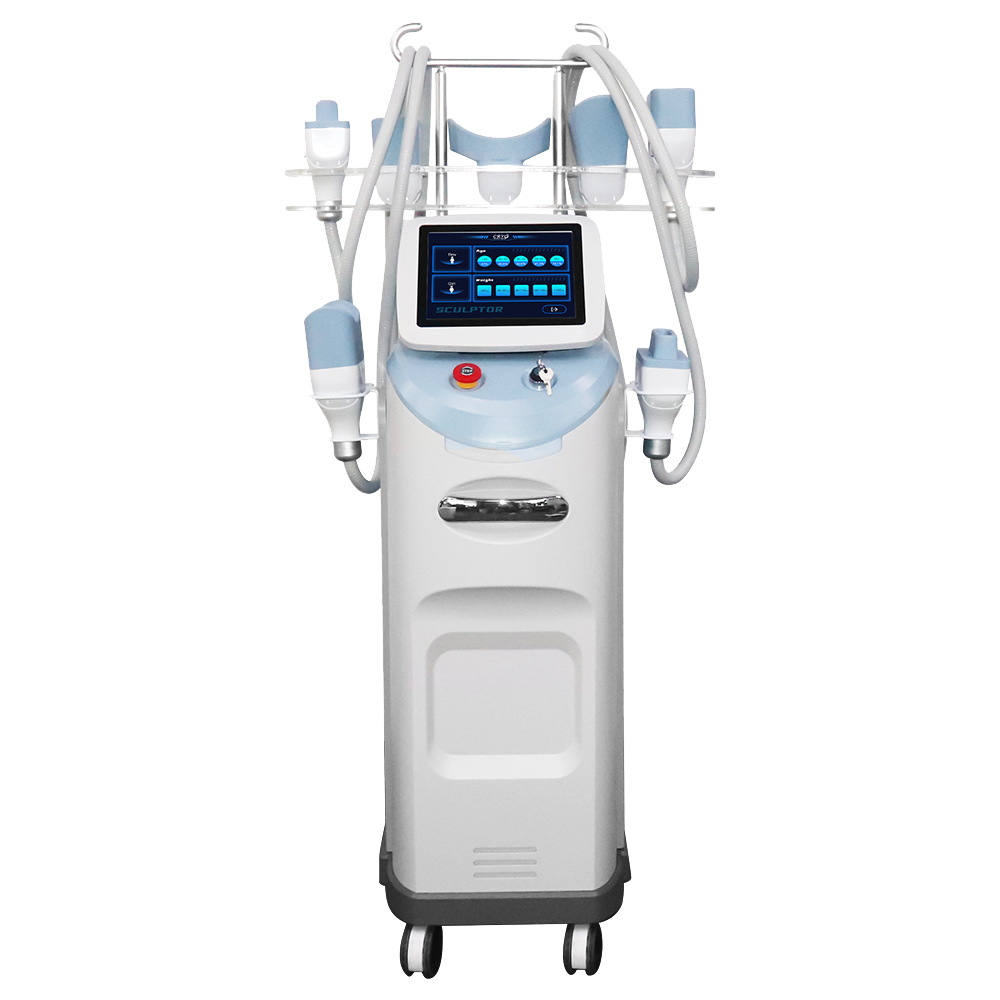

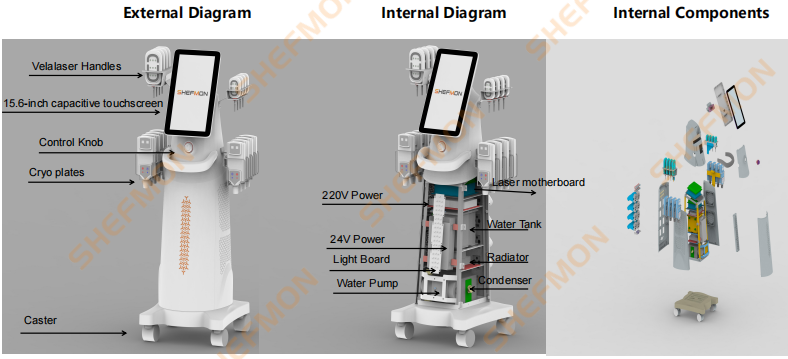

A professional supply system starts with a clearly defined and transparent composition structure. At our factory, every machine is designed with both external and internal architecture in mind, ensuring performance stability and long-term serviceability.

1.1 External Structure Design and Clarity

We clearly define all external components of our machines, such as treatment handles, control knobs, cryo plates, casters, and large-format capacitive touchscreens. This structured external layout improves ergonomics, simplifies operation, and allows buyers to understand how each component contributes to treatment performance and user experience.

Standardized external components also improve replacement efficiency and reduce maintenance complexity during after-sales service.

1.2 Internal Structure and Functional Layout

Internally, our machines are designed with a logical and engineering-driven layout. Core components such as laser motherboards, power modules (220V and 24V), water tanks, light boards, pumps, radiators, and condensers are securely positioned to minimize vibration and thermal stress.

By maintaining a clean and organized internal structure, our factory improves heat dissipation efficiency, reduces interference between modules, and significantly lowers the risk of system instability during long-term operation.

2. Machine Enclosure Materials: A Core Supply Decision

The machine enclosure is a key element of our supply system, directly affecting durability, appearance, production efficiency, and after-sales cost. At Shefmon, we evaluate enclosure solutions based on production scale, performance requirements, and long-term reliability.

2.1 Hand-Assembled Machine Enclosures

Hand-assembled enclosures rely entirely on manual assembly and adhesive bonding. In our evaluation, this solution is only suitable for very small-batch or temporary customization projects.

While hand-assembled enclosures require low initial investment and minimal tooling, they suffer from low production efficiency and high per-unit costs. Adhesive bonding is prone to cracking, sinking, and aging, leading to visible seams, poor color consistency, and unstable structural integrity. Due to the lack of standardized structure, disassembly and repair are difficult and often cause secondary damage.

2.2 Sheet Metal Machine Enclosures

Sheet metal enclosures offer improved structural strength and impact resistance and are commonly used in medium-batch production. CNC-assisted processing allows a certain level of automation without mold investment.

However, from our manufacturing experience, sheet metal enclosures have clear limitations. Welding quality varies, surface treatments lack consistency, and seam differences between welded sections can reach several millimeters. Complex curved designs are difficult to achieve, limiting product differentiation. Repairs are labor-intensive, often requiring cutting and re-welding, which increases long-term after-sales costs.

2.3 Injection-Molded Machine Enclosures

For scalable and professional production, our factory prioritizes injection-molded enclosures. This solution offers extremely high production efficiency, excellent consistency, and superior appearance control.

Once mold investment is amortized, injection molding provides a low unit cost suitable for large-scale manufacturing. Reinforcing ribs enhance structural strength, while integrated clips and standardized snap or screw connections simplify assembly and disassembly. Injection molding also allows complex curves, refined surface finishes, and consistent color integration.

Although mold development requires higher upfront investment and longer preparation time, this approach delivers the best balance between quality, efficiency, and long-term reliability.

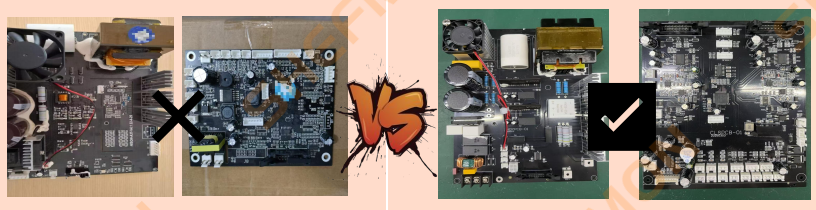

3. PCB Engineering as the Core of Supply System Reliability

At Shefmon, we treat PCB engineering as a critical pillar of our supply system, especially for high-frequency and magnetostimulation-based devices.

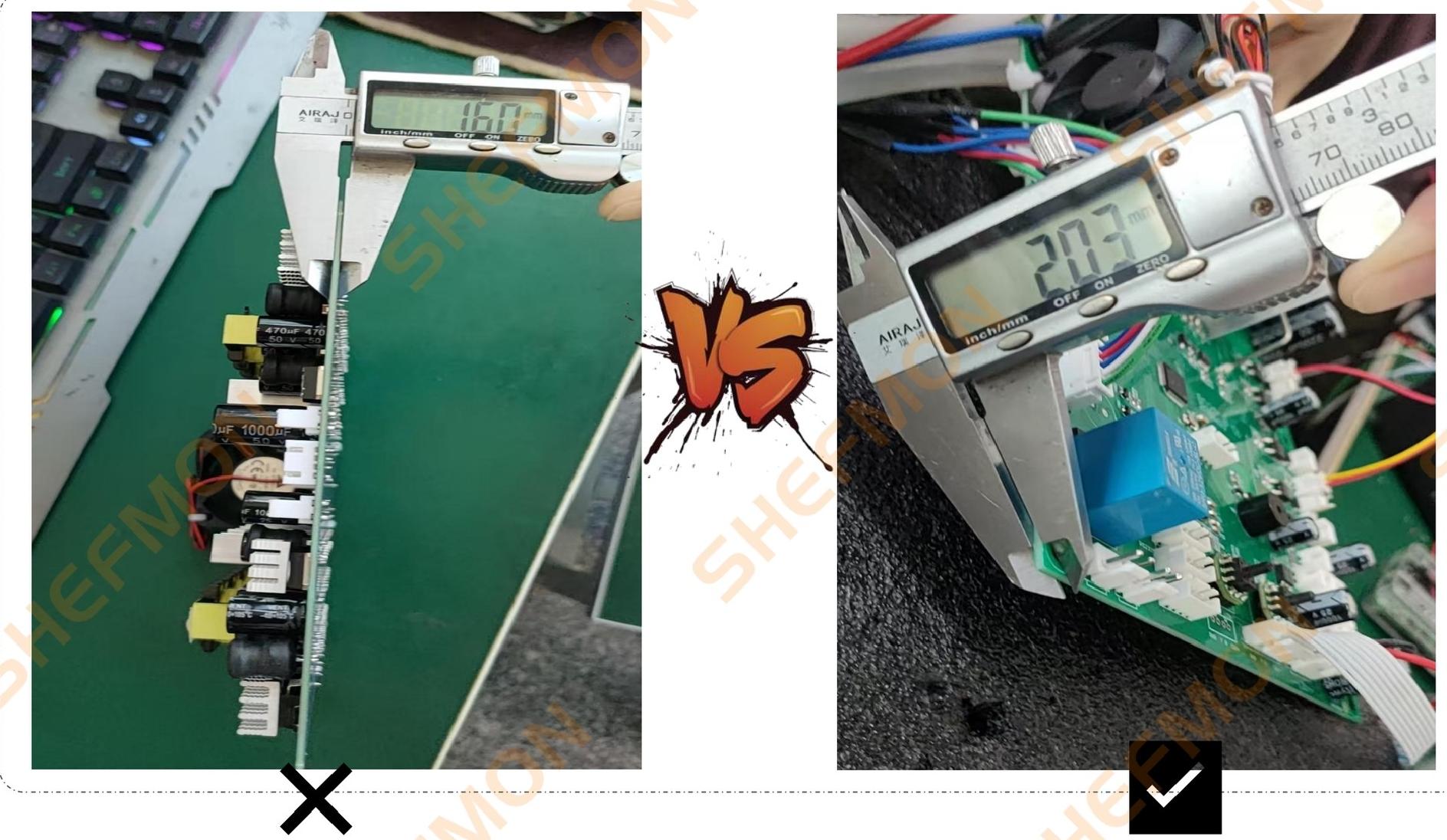

3.1 PCB Thickness and Mechanical Stability

Many market solutions still use 1.6 mm PCB boards, which are vulnerable to vibration and high-frequency operation. Under continuous use, these boards face a higher risk of fracture and circuit failure.

Our factory adopts a 2.0 mm thickened PCB design, improving bending resistance and vibration robustness by approximately 40%. This structural reinforcement significantly enhances long-term stability in demanding operating environments.

3.2 IGBT and Transformer Selection

Standard low-frequency IGBT and transformer solutions often experience temperature rises exceeding 100°C, resulting in distorted output waveforms and unstable energy delivery. These issues directly affect treatment effectiveness and user comfort.

Our in-house developed power management and system control PCBs use high-frequency, low-loss IGBTs combined with active cooling designs. Operating temperatures are controlled at ≤70°C, improving waveform accuracy by around 20% and ensuring stable high-frequency pulse output required for magnetostimulation applications.

3.3 MOSFET Precision and Current Protection

Low-voltage MOSFETs commonly used in commercial designs are prone to breakdown and current fluctuations greater than 15%, leading to sudden shutdowns or burnout.

We select high-voltage-resistant MOSFETs with low internal resistance, maintaining current fluctuation below 5%. Real-time current monitoring and overcurrent protection with response times of ≤10 ms effectively prevent damage and extend service life by more than three times.

3.4 Copper Foil Thickness and Thermal Performance

To handle high peak currents, our PCBs use 2 μm oxygen-free, high-thermal-conductivity copper foil instead of standard 1 μm electrolytic copper. This doubles current-carrying capacity and improves heat dissipation efficiency by 50%, eliminating overheating risks at solder joints and critical pathways.

Conclusion

At Shefmon, evaluating and building a professional beauty equipment supply system means controlling every structural, material, and electronic detail from the factory level. Transparent composition design, advanced enclosure manufacturing, and high-standard PCB engineering form the foundation of our supply philosophy. These elements ensure stable performance, scalable production, and long-term reliability for our partners.