Share optimized solutions, professional valve knowledge and industry news

Please enter the relevant terms or keywords you need to consult, and relevant articles will appear in the search results. If you can’t find the answer you need, please feel free to contact us and we will be happy to help. Or you can directly send an email to beauty@shefmon.com

Shefmon Factory Strength: 10+ Years of Experience in Chinese OEM Beauty Equipment

- shefmon

Since 2014, Shefmon has grown from a specialized manufacturing facility into a trusted global partner for Chinese OEM beauty equipment. With over a decade of hands-on experience, Shefmon combines engineering expertise, strict quality control, and flexible customization to support beauty brands, distributors, and clinic operators worldwide. This article outlines Shefmon’s core strengths, manufacturing capabilities, and why global clients choose Shefmon as their long-term OEM supplier.

1. A Decade of Focused Experience in OEM Beauty Equipment

1.1 Founded in 2014 with a Clear OEM Mission

Shefmon was established in 2014 with a single goal: to deliver reliable, customizable, and competitively priced beauty equipment for global brands. From the beginning, the company focused exclusively on OEM and ODM manufacturing rather than retail sales. This allowed Shefmon to refine production processes, invest in specialized machinery, and build a technical team dedicated to product development and quality assurance.

Over the past 10+ years, Shefmon has accumulated deep industry knowledge across multiple beauty technologies, including body slimming, cryotherapy, RF skin tightening, cavitation, laser systems, EMS, and multifunction platforms.

1.2 Long-Term Partnerships Across Global Markets

Shefmon serves clients in North America, Europe, the Middle East, Southeast Asia, and Latin America. Many of these clients have worked with Shefmon for more than five years, reflecting consistent quality, stable lead times, and dependable after-sales support.

By understanding regulatory requirements, market preferences, and usage conditions in different regions, Shefmon continuously adapts product designs and technical standards to meet international expectations.

2. Comprehensive Manufacturing Capabilities

2.1 In-House Production Facilities

Shefmon operates its own production workshops covering:

-

Sheet metal fabrication and CNC machining

-

Plastic injection molding

-

Electronic assembly and wiring

-

Module integration and system testing

-

Final assembly and packaging

This vertical integration gives Shefmon full control over production quality, lead times, and cost efficiency.

2.2 Advanced Equipment and Process Control

Shefmon invests consistently in modern manufacturing equipment, including:

-

High-precision CNC machines

-

Automatic wire harness assembly systems

-

SMT lines for PCB production

-

Laser marking and engraving systems

-

Environmental stress testing equipment

Each production stage follows standardized operating procedures (SOPs), ensuring consistency across large-volume orders and custom-built units.

3. Strong R&D and Product Customization Capability

3.1 Dedicated R&D Engineering Team

Shefmon maintains a professional R&D team composed of mechanical engineers, electrical engineers, software developers, and industrial designers. This team is responsible for:

-

New product development

-

Existing product upgrades

-

Functional module optimization

-

Firmware and software interface design

-

Safety system enhancement

By integrating customer feedback and market trends into the development process, Shefmon ensures that its OEM equipment remains competitive and compliant.

3.2 Flexible OEM and ODM Services

Shefmon offers both OEM and ODM services to meet different branding needs:

OEM services include:

-

Logo printing and laser engraving

-

Housing color customization

-

Software interface branding

-

Packaging and manual customization

ODM services include:

-

Structural redesign

-

Functional module integration

-

New control system development

-

Private mold creation

-

Exclusive product models

This flexibility allows Shefmon’s clients to launch differentiated products under their own brand identity.

4. Strict Quality Control and International Compliance

4.1 Multi-Stage Quality Inspection System

Quality control is embedded throughout Shefmon’s production workflow:

-

Incoming material inspection

-

In-process quality checks

-

Functional performance testing

-

Electrical safety testing

-

Aging test before shipment

Each unit is tested for stability, output accuracy, and system reliability before packaging.

4.2 Compliance with Global Standards

Shefmon’s OEM beauty equipment is manufactured to meet international regulatory requirements, including:

-

CE certification for European markets

-

FCC standards for electromagnetic compatibility

-

RoHS compliance for material safety

-

ISO-based quality management processes

This ensures that clients can import, distribute, and operate Shefmon equipment in multiple regions with confidence.

5. Wide Product Portfolio for Multiple Market Segments

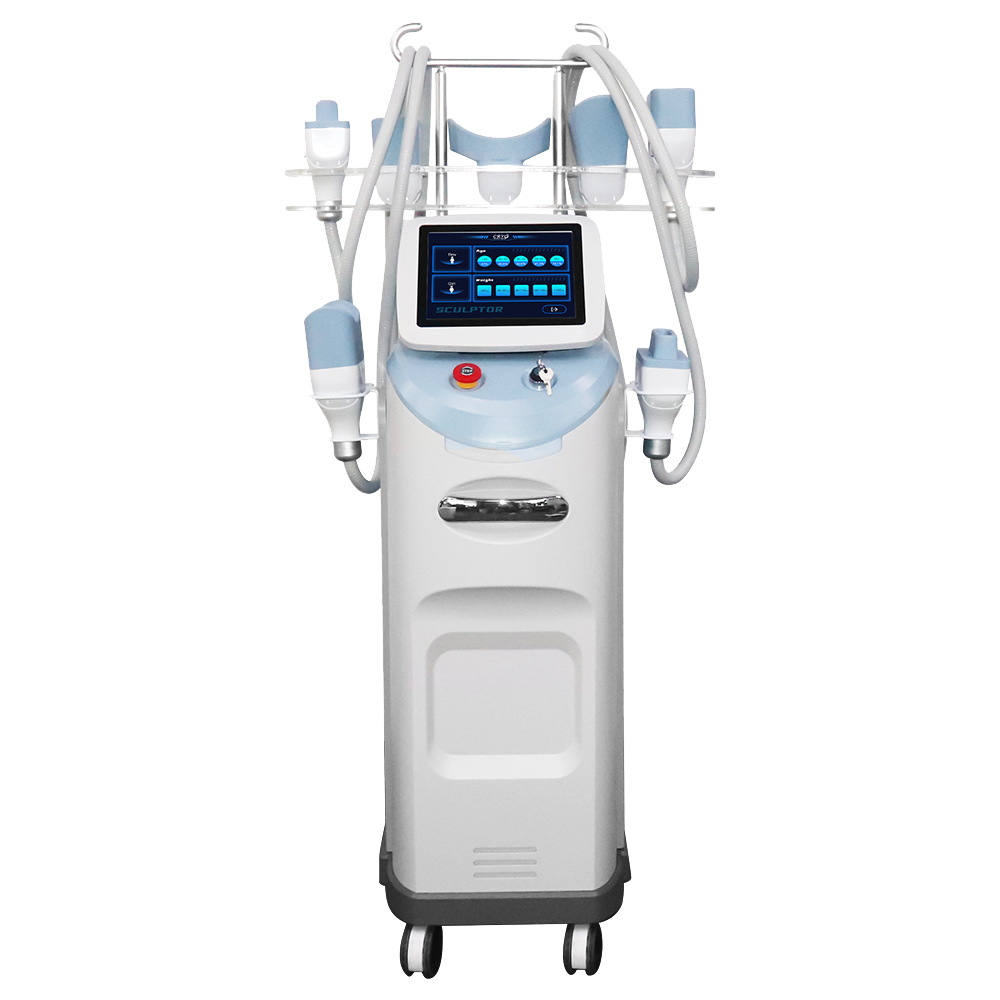

5.1 Body Slimming and Fat Reduction Equipment

Shefmon manufactures various non-invasive slimming devices, including:

-

Cryotherapy machines

-

Cavitation slimming machines

-

EMS body sculpting systems

-

RF fat reduction platforms

These systems support fat burning, localized fat removal, cellulite reduction, and body contouring.

5.2 Skin Tightening and Rejuvenation Devices

Shefmon provides professional skin care equipment, such as:

-

RF skin tightening machines

-

HIFU lifting systems

-

Laser rejuvenation devices

-

Multifunction facial platforms

These products are designed for skin tightening, collagen stimulation, wrinkle reduction, and facial shaping.

5.3 Muscle Recovery and Wellness Equipment

Shefmon also produces wellness-oriented systems, including:

-

Cryotherapy recovery machines

-

EMS muscle stimulation devices

-

Massage therapy equipment

These systems are used in sports recovery centers, physiotherapy clinics, and wellness spas.

6. Efficient Production Capacity and Delivery Management

6.1 Scalable Production Output

Shefmon’s factory is designed to handle both small batch customization and large-scale production. Whether clients need 5 units for market testing or 500 units for national distribution, Shefmon can scale output without compromising quality.

Production capacity is supported by:

-

Modular assembly lines

-

Flexible labor allocation

-

Lean manufacturing principles

6.2 Stable Lead Times and Export Logistics

Typical lead times range from 15 to 35 working days depending on customization level and order quantity. Shefmon works closely with experienced freight forwarders to arrange:

-

Air freight

-

Sea freight

-

Rail transport

-

Door-to-door delivery

Export packaging is designed to protect equipment during long-distance transportation.

7. Professional After-Sales and Technical Support

7.1 Comprehensive Documentation and Training

Shefmon provides:

-

User manuals

-

Technical diagrams

-

Operation training videos

-

Maintenance guidelines

These resources help distributors and clinic staff operate and maintain equipment properly.

7.2 Spare Parts and Warranty System

Shefmon offers:

-

Standard warranty coverage

-

Long-term spare parts supply

-

Remote technical support

-

Troubleshooting assistance

This reduces downtime and protects clients’ long-term investments.

8. Why Global Clients Choose Shefmon

8.1 Competitive Pricing Without Compromising Quality

As a direct OEM factory, Shefmon eliminates middleman costs while maintaining high manufacturing standards. This gives clients better profit margins and pricing stability.

8.2 Customization Flexibility and Fast Response

Shefmon’s project management team ensures:

-

Rapid quotation turnaround

-

Clear technical communication

-

Efficient sample development

-

On-time mass production

8.3 Long-Term Partnership Mindset

Shefmon views every OEM project as a long-term collaboration rather than a one-time transaction. Continuous improvement, technical upgrades, and market feedback integration are core values.

9. Future Development and Innovation Strategy

9.1 Investment in Smart Manufacturing

Shefmon is upgrading production systems with:

-

Digital production tracking

-

Automated quality inspection

-

Smart inventory management

These initiatives improve efficiency, traceability, and consistency.

9.2 Expansion of Product Lines

Future development focuses on:

-

AI-integrated beauty equipment

-

Smart control interfaces

-

Portable beauty devices

-

Energy-efficient systems

These innovations aim to meet evolving market demands.

10. Conclusion

With over 10 years of experience in Chinese OEM beauty equipment, Shefmon has established itself as a reliable, professional, and innovation-driven manufacturing partner. From in-house production and strong R&D capabilities to strict quality control and flexible customization services, Shefmon delivers comprehensive OEM solutions for global beauty brands.

By combining factory-direct pricing, international compliance, and long-term partnership values, Shefmon continues to empower distributors, clinics, and brand owners to build competitive product lines with confidence.

For companies seeking a stable, experienced, and scalable OEM factory in China, Shefmon stands as a proven choice backed by more than a decade of industry expertise.