Share optimized solutions, professional valve knowledge and industry news

Please enter the relevant terms or keywords you need to consult, and relevant articles will appear in the search results. If you can’t find the answer you need, please feel free to contact us and we will be happy to help. Or you can directly send an email to beauty@shefmon.com

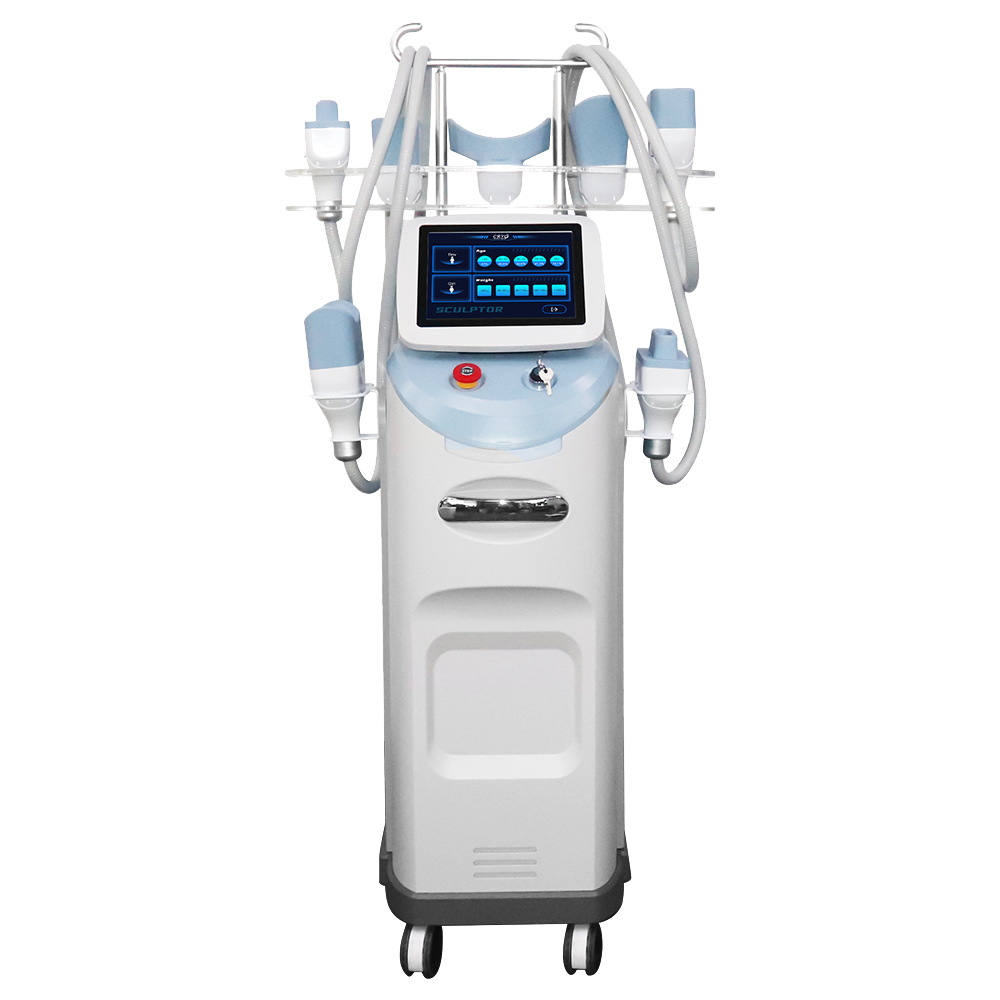

What Technologies Are Needed for the Manufacturing of Beauty Devices?

Introduction to Beauty Device Manufacturing

The beauty industry has come a long way from simple creams and lotions. Today, beauty devices look more like compact pieces of medical-grade technology than traditional cosmetic tools. From facial cleansing brushes to RF skin tightening machines, modern beauty devices rely on a complex ecosystem of technologies working together seamlessly.

The Rapid Growth of the Beauty Technology Industry

Beauty tech is booming—and for good reason. Consumers want visible results, convenience, and professional-grade treatments at home or in clinics. This demand has pushed manufacturers to adopt cutting-edge technologies that deliver precision, safety, and performance. Think of it like upgrading from a bicycle to a smart electric car—same purpose, totally different experience.

Why Advanced Manufacturing Technologies Matter

Without advanced manufacturing technologies, beauty devices would be bulky, unreliable, or unsafe. Precision engineering ensures consistent performance, while smart software enhances usability. In short, technology is the backbone that turns an idea into a market-ready beauty device.

Core Engineering Technologies

Mechanical Engineering in Beauty Devices

Mechanical engineering is the skeleton of beauty devices. It defines structure, durability, and ergonomics.

Precision Components and Ergonomic Design

Every button, curve, and internal mechanism must be designed with millimeter-level accuracy. Precision gears, motors, and housings ensure smooth operation, while ergonomic design makes devices comfortable to hold and easy to use—because nobody wants a skincare tool that feels like a brick.

Electrical and Electronic Engineering

Electronic engineering brings beauty devices to life.

Circuit Design and Power Management

From RF devices to LED masks, reliable circuit design ensures stable output and prevents overheating or power fluctuations. Advanced power management systems protect both the device and the user, maintaining consistent performance across sessions.

Embedded Systems and Software Development

Microcontrollers and Firmware

At the heart of most beauty devices lies a microcontroller. This tiny brain controls temperature, intensity, timing, and safety mechanisms. Firmware ensures everything runs smoothly, like a conductor leading an orchestra.

User Interface and Smart Controls

Touch buttons, LED indicators, and digital screens rely on software development. Intuitive UI design makes devices easy to operate, even for first-time users. Smart controls also allow customization, so users can tailor treatments to their skin needs.

Sensor Technologies

Temperature, Pressure, and Motion Sensors

Sensors act as the device’s senses. Temperature sensors prevent burns, pressure sensors ensure proper contact with the skin, and motion sensors enhance safety by detecting incorrect usage.

Skin Detection and Feedback Systems

Advanced devices can detect skin resistance or moisture levels and adjust output automatically. It’s like having a built-in skincare expert constantly monitoring and adjusting treatments in real time.

Energy and Power Technologies

Battery Technology and Charging Systems

Lithium-ion batteries dominate beauty devices due to their high energy density and long lifespan. Fast charging and wireless charging technologies add convenience, especially for portable devices.

Energy Efficiency and Heat Management

Efficient energy usage reduces heat generation and extends battery life. Heat dissipation technologies—such as thermal pads and ventilation designs—keep devices cool and safe.

Aesthetic and Industrial Design Technologies

3D Modeling and CAD Software

Before a device ever exists physically, it’s built digitally. CAD software allows engineers and designers to simulate performance, stress points, and assembly processes.

Prototyping and Rapid Iteration

3D printing and rapid prototyping enable fast testing and refinement. This shortens development cycles and ensures the final product meets both functional and aesthetic standards.

Manufacturing and Production Technologies

Injection Molding and CNC Machining

Injection molding creates precise plastic components at scale, while CNC machining produces high-accuracy metal parts. Together, they ensure consistency and durability.

Automated Assembly Lines

Automation improves efficiency and reduces human error. Robotic assembly lines can handle delicate components with precision that manual labor simply can’t match.

Surface Treatment and Finishing Technologies

Coating, Polishing, and Texturing

Surface treatments enhance appearance and performance. Anti-scratch coatings, soft-touch finishes, and polished metals elevate the user experience.

Durability and Skin-Safe Finishes

Beauty devices must be safe for prolonged skin contact. Medical-grade coatings and hypoallergenic materials prevent irritation and improve longevity.

Quality Control and Testing Technologies

Reliability and Safety Testing

Devices undergo rigorous testing for electrical safety, durability, and performance stability. Drop tests, aging tests, and stress tests ensure reliability.

Compliance with International Standards

Manufacturers must comply with CE, FDA, and other international certifications. Compliance technologies ensure products meet global safety and quality requirements.

Smart Manufacturing and Industry 4.0

IoT Integration in Production

IoT-enabled factories monitor machines, track defects, and optimize production in real time. This increases efficiency and reduces waste.

Data-Driven Manufacturing Decisions

Big data analytics help manufacturers predict failures, improve yields, and refine product designs based on real-world performance.

Sustainability and Green Technologies

Eco-Friendly Materials

Biodegradable plastics, recyclable metals, and reduced packaging help lower environmental impact—an increasingly important factor for modern consumers.

Energy-Saving Production Processes

Energy-efficient machinery and optimized workflows reduce carbon footprints and production costs simultaneously. A win-win situation.

Customization and OEM/ODM Technologies

Modular Design Systems

Modular designs allow easy customization for different markets or brands. One core device, many variations.

Branding and Product Differentiation

Laser engraving, color customization, and UI branding technologies help OEM and ODM manufacturers meet diverse client needs.

Future Technologies in Beauty Device Manufacturing

AI and Machine Learning Applications

AI can personalize treatments, analyze usage data, and even predict skin responses. The future of beauty devices is intelligent and adaptive.

Wearable and Connected Beauty Devices

Connected devices sync with mobile apps, offering progress tracking and personalized recommendations. Beauty is becoming smarter—and more personal.

Challenges in Beauty Device Manufacturing

Balancing Innovation and Cost

Advanced technologies can be expensive. Manufacturers must balance cutting-edge features with cost efficiency to remain competitive.

Regulatory and Safety Challenges

Strict regulations require constant updates and compliance efforts. Safety always comes first, especially in skin-contact devices.

Conclusion

Beauty device manufacturing is no longer just about assembling parts—it’s about integrating advanced technologies across engineering, software, design, and sustainability. As consumer expectations rise, manufacturers must continue innovating to deliver safer, smarter, and more effective devices. The future of beauty lies at the intersection of technology and creativity, and the possibilities are just getting started.

FAQs

1. What is the most important technology in beauty device manufacturing?

Embedded systems and sensor technologies are crucial, as they ensure safety, precision, and performance.

2. Are beauty devices considered medical devices?

Some are classified as medical devices depending on their function and region, requiring stricter compliance and testing.

3. How does AI improve beauty devices?

AI enables personalized treatments, adaptive intensity control, and data-driven skincare recommendations.

4. Why is surface treatment important in beauty devices?

It improves durability, aesthetics, and ensures the device is safe for skin contact.

5. What trends will shape the future of beauty device manufacturing?

AI integration, smart connectivity, sustainability, and customization will dominate future developments.